Laser cladding: the magical "reshaping" of the metal surface

In the precision world of the manufacturing industry, laser coating is like a "gold magic" at the micro level, which is quietly but unstoppably revolutioning the life and performance upgrade path of parts.

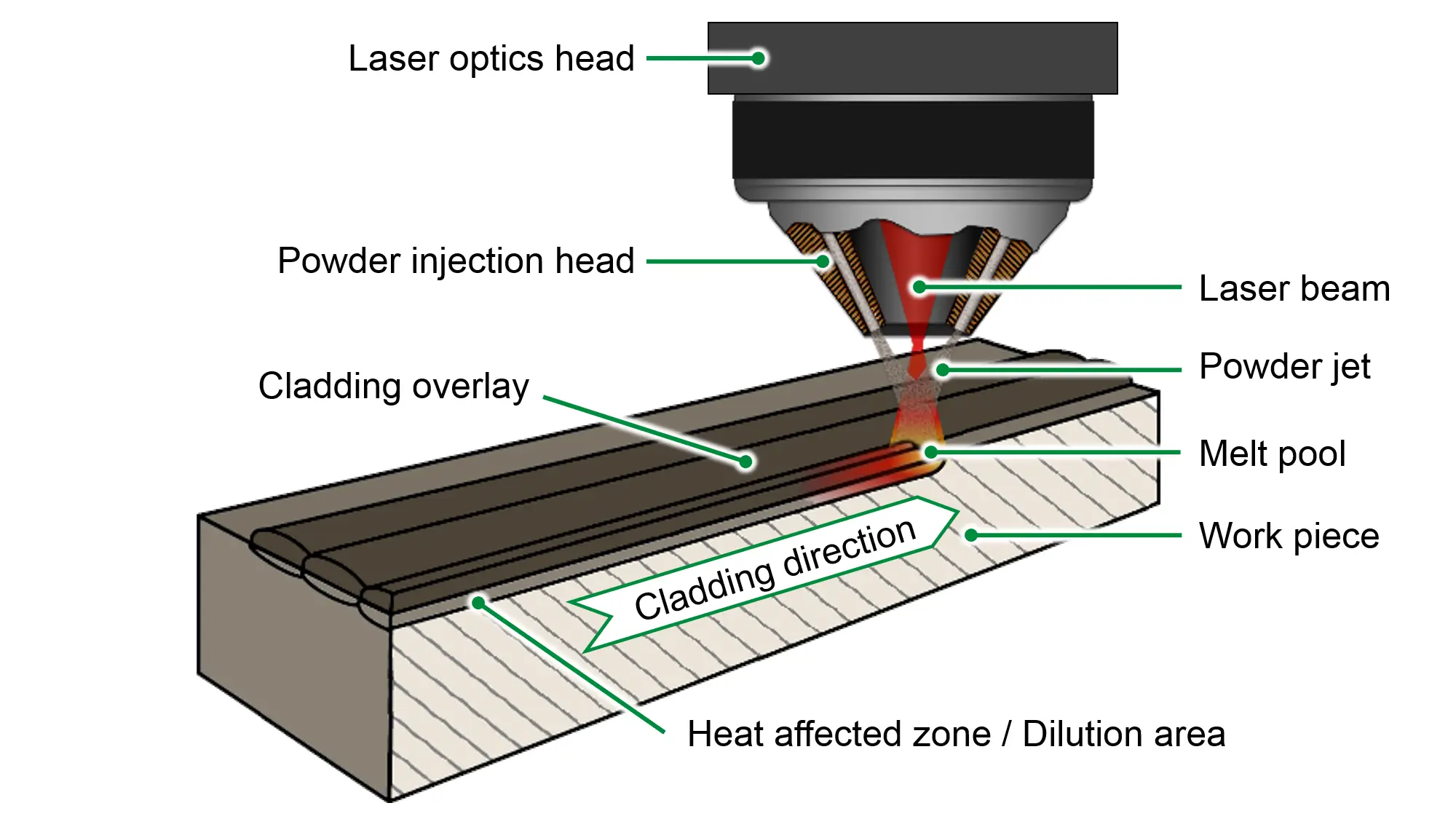

Laser fusion is essentially a feast of material fusion with high energy density. It activates a high-power laser beam, which is a highly focused light beam like a fine and hot welding gun, accurately sweeping the surface of metal parts. At the touch of the beam, the preset alloy powder or the filament filling material directly transported is instantly heated to a molten state, and then cooled rapidly to achieve a seamless metallurgical combination with the matrix metal. From the turbine blades of the aircraft engine to the drill rod of oil exploration, the surface, which was originally overloaded and prone to wear and corrosion in the harsh environment, has been covered with a layer of "customized armor" by laser melting, and the hardness, wear resistance and corrosion resistance have been greatly improved.

The reason why this technology is so attractive is that the accuracy is the first. The laser can focus on extremely fine areas, such as repairing damage in key parts of rice grain-sized parts, and will not implicate the surrounding area, which can be called a savior in precision mold repair, revitalizing expensive molds and sharply reducing costs. In addition, the choice of fusion coating materials is wide, and engineers can match them on demand to modify exclusive formulas suitable for different working conditions. Whether it is high-temperature resistant nickel-based alloys or high-hardness tungsten carbide ceramic composites, they can be firmly attached.

Looking at the wave of Industry 4.0, laser cladding is deeply integrated with automation and intelligence. With the help of the robotic arm, it can flexibly control the melting path, cooperate with the sensor to monitor the melting quality in real time, and analyze the massive data backflow, so that each melting is perfect. It is not only a wonderful way to remedy old parts, but also a powerful tool for the forward-looking design of new products with super performance, helping the manufacturing industry to gallop all the way on the track of high-quality development and break through the limitations of traditional materials.

激光熔覆:金属表面的神奇“重塑术”

在制造业的精密世界里,激光熔覆宛如一场微观层面的“点金魔法”,正悄无声息却又势不可挡地革新着零部件的延寿与性能升级路径。

激光熔覆,本质上是一场高能量密度的材料融合盛宴。它启用高功率激光束,这束能量高度聚焦的光如同细密又炽热的焊枪,精准地扫过金属部件表面。在光束触及之处,预置的合金粉末或是直接输送过来的丝状填充材料,瞬间被加热到熔融状态,随后急速冷却,与基体金属达成天衣无缝的冶金结合。从航空发动机的涡轮叶片,到石油开采的钻杆,原本在严苛环境下不堪重负、易被磨损腐蚀的表面,经激光熔覆披上一层“定制铠甲”,硬度、耐磨与耐蚀性大幅跃升。

这项技术之所以魅力非凡,精准度首当其冲。激光能够聚焦到极细微区域,像是在米粒大小的零件关键部位修复损伤,也不会牵连周边分毫,这在精密模具修复里堪称救星,让昂贵模具重焕新生,成本锐减。再者,熔覆材料选择宽泛,工程师按需搭配,调制出契合不同工况的独家配方,不管是抗高温的镍基合金,还是高硬度的碳化钨陶瓷复合材料,都能稳稳附着。

放眼工业4.0浪潮,激光熔覆更是与自动化、智能化深度融合。借助机械臂灵活操控熔覆路径,配合传感器实时监测熔覆质量,海量数据回流分析,让每一次熔覆都趋于完美。它不只是补救老旧部件的妙法,更是前瞻性设计超强性能新品的利器,助力制造业在高质量发展的赛道上一路疾驰,冲破传统材料局限的枷锁。

Laser cladding: the magical &q

Laser cladding: the magical &q