Laser cutting offers the following advantages

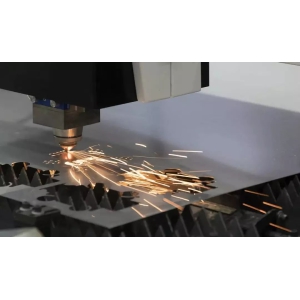

Laser cutting offers the following advantages:

1. **High Precision**

Laser cutting can achieve a precision of ±0.mm, making it suitable for complex shapes and high-precision requirements.

2. **High Quality**

The cut surface is smooth and free of burrs, reducing need for secondary processing and improving product quality.

3. **High Efficiency**

Laser cutting is fast, especially suitable for mass production, significantly improving efficiency.

4 **Non-Contact Processing**

Laser cutting does not require physical contact, avoiding material deformation or damage, and is suitable for fragile or thin materials.

5.Strong Material Adaptability**

It is suitable for a variety of materials such as metal, plastic, ceramic, glass, etc., with a wide range of applications.

. **High Degree of Automation**

It can be integrated with automated equipment to achieve fully automatic production, reducing manual intervention.

7. **High Flexibility**

ly switch cutting patterns through programming, adapting to small batch, multi-variety production.

8. **Energy Saving and Environmental Protection**

Compared with traditional, laser cutting has low energy consumption and less waste, making it more environmentally friendly.

9. **Complex Shape Processing**

It can easily handle complex geometric shapes, for high-complexity designs.

10. **Small Heat-Affected Zone**

The laser beam is concentrated, with a small heat-affected zone, reducing material deformation and thermal damage.

These advantages make laser cutting widely used in the manufacturing industry.

激光切割具有以下优点:

1. **高精度**

激光切割精度可达±0.1mm,适合复杂形状和高精度要求的加工。

2. **高质量**

切口光滑,无毛刺,减少后续加工需求,提升产品质量。

3. **高效率**

激光切割速度快,尤其适合大批量生产,显著提高效率。

4. **非接触加工**

激光切割无需物理接触,避免材料变形或损伤,适合易碎或薄材料。

5. **材料适应性强**

适用于金属、塑料、陶瓷、玻璃等多种材料,应用范围广泛。

6. **自动化程度高**

可与自动化设备集成,实现全自动生产,减少人工干预。

7. **灵活性高**

通过编程快速切换切割图案,适应小批量、多品种生产。

8. **节能环保**

相比传统切割,激光切割能耗低,废料少,更环保。

9. **复杂形状加工**

可轻松处理复杂几何形状,适合高复杂度设计。

10. **热影响区小**

激光束集中,热影响区小,减少材料变形和热损伤。

这些优点使激光切割在制造业中广泛应用。

Application of laser cutting i

Application of laser cutting i

Application of laser cutting i

Application of laser cutting i

Laser cutting is widely used i

Laser cutting is widely used i

The advantage of laser tube cu

The advantage of laser tube cu