Laser cutting is widely used in the furniture manufacturing industry

Laser cutting is widely used in the furniture manufacturing industry. The following are some of the main aspects:

Plate Cutting

• Precise Blank Sizing: It can accurately cut various plates such as medium - density fiberboard, particleboard, and solid wood boards into the required shapes and sizes according to the design drawings. The error can be controlled within a very small range, improving material utilization and reducing waste.

• Cutting of Complex Shapes: It can easily achieve the cutting of complex patterns and shapes such as curves, arcs, and irregular shapes. This provides possibilities for innovative furniture design and can meet the market demands for personalization and customization.

Component Processing

• Mortise - and - Tenon Structure Processing: It can accurately cut tenons and mortises, ensuring the matching accuracy between them, enhancing the stability and firmness of the furniture structure, and improving the quality and service life of the furniture.

• Engraving and Hollowing - out: Through laser cutting, engraving can be carried out on the surface of furniture components, or various hollow - out patterns can be cut out, increasing the artistic sense and decorative effect of the furniture and creating a unique visual effect.

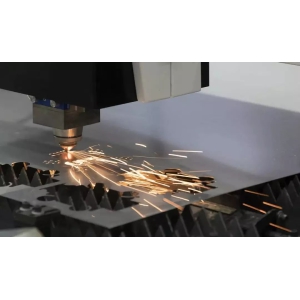

Metal Component Processing

• Cutting of Hardware Fittings: For metal hardware fittings in furniture, such as handles, hinges, and decorative strips, laser cutting can quickly and accurately complete the cutting task, ensuring the dimensional accuracy and surface quality of the fittings.

• Cutting of Metal Frames: It can cut metal pipes or plates for making the frame structure of furniture. The cutting surface is smooth without burrs, and the cutting speed is fast, which can improve production efficiency.

Leather and Fabric Cutting

• Leather Cutting: When making upholstered furniture or leather decorative parts, laser cutting can accurately cut leather materials. The cutting edge is neat, without fraying or thread - slipping, and at the same time, it can avoid damage to the leather material.

• Fabric Cutting: For fabrics used in furniture such as curtains and sofa covers, laser cutting can be carried out precisely according to the design requirements. In addition, batch cutting can be achieved through programming, improving production efficiency.

Identification and Marking

• Cutting of Brand Logos: Brand logos or trademark patterns can be cut out at prominent or hidden parts of the furniture, playing a role in brand promotion and product traceability.

• Marking of Product Information: Product models, specifications, production dates, and other information can be cut on furniture components, facilitating production management and quality control.

激光切割在家具制造行业有广泛应用,以下是一些主要方面:

板材切割

• 精准下料:能根据设计图纸将各种板材如中密度纤维板、刨花板、实木板等精准切割成所需的形状和尺寸,误差可控制在极小范围内,提高材料利用率,减少浪费。

• 复杂造型切割:可轻松实现如曲线、弧形、异形等复杂图案和造型的切割,为家具设计的创新提供了可能,能满足个性化、定制化的市场需求。

零部件加工

• 榫卯结构加工:能精准切割出榫头和榫眼,保证二者的配合精度,增强家具结构的稳定性和牢固性,提升家具的品质和使用寿命。

• 雕刻与镂空:通过激光切割可在家具零部件表面进行雕刻,或切割出各种镂空图案,增加家具的艺术感和装饰性,打造独特的视觉效果。

金属部件加工

• 五金配件切割:对于家具中的金属五金配件,如拉手、合页、装饰条等,激光切割可快速、精确地完成切割任务,保证配件的尺寸精度和表面质量。

• 金属框架切割:能对金属管材或板材进行切割,用于制作家具的框架结构,切割面光滑,无毛刺,且切割速度快,可提高生产效率。

皮革与织物切割

• 皮革切割:在制作软包家具或皮革装饰件时,激光切割能精确地切割皮革材料,切割边缘整齐,不会出现毛边、脱线等问题,同时还能避免对皮革材质的损伤。

• 织物切割:对于用于家具的窗帘、沙发套等织物,激光切割可以按照设计要求进行精准切割,还可通过编程实现批量切割,提高生产效率。

标识与标记

• 品牌标识切割:可在家具的显眼位置或隐蔽部位切割出品牌标识或商标图案,起到品牌宣传和产品追溯的作用。

• 产品信息标记:能在家具零部件上切割出产品型号、规格、生产日期等信息,方便生产管理和质量控制。

Application of laser cutting i

Application of laser cutting i

Application of laser cutting i

Application of laser cutting i

Laser cutting is widely used i

Laser cutting is widely used i

The advantage of laser tube cu

The advantage of laser tube cu