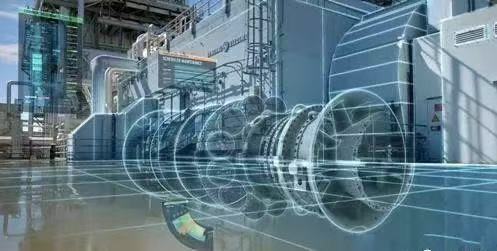

Application of laser cutting in aerospace manufacturing

Laser cutting plays a significant role in the field of aerospace manufacturing, mainly reflected in the following aspects:

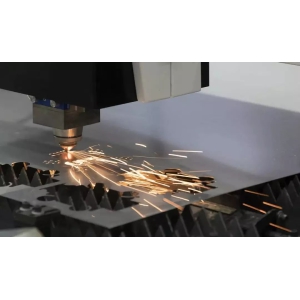

## 1. **High-precision Cutting**

- **Complex Parts**: Laser cutting can precisely process aerospace materials such as titanium alloys and aluminum alloys, meeting the requirements complex geometric shapes.

- **Micro-hole Machining**: Suitable for micro-hole machining of parts such as engine blades, with precision reaching the micron level.

###2. **Efficient Production**

- **Fast Cutting**: Laser cutting has a fast speed, especially suitable for mass production, improving efficiency.

- **Automation Integration**: be combined with automated systems to achieve continuous operation, reducing manual intervention.

### 3. **Material Adaptability**

- **Various Materials**: Suitable for a of aerospace materials such as titanium alloys, aluminum alloys, and composite materials.

- **Hard-to-machine Materials**: The cutting effect on high-strength, high-hardness is significant.

### 4. **Small Heat-affected Zone**

- **Reduce Deformation**: Laser cutting has a small heat-affected zone, reducing deformation and maintaining material properties.

- **High-quality Cut Surface**: The cut surface is smooth, reducing the need for subsequent processing.

### 5. **weight Design**

- **Weight Reduction**: Through precise cutting, it helps to achieve the lightweight design of aircraft, improving fuel efficiency.

- **Optimized Structure**: Supports design of complex structures, enhancing overall performance.

### 6. **Environmental Protection and Cost**

- **No Tool Wear**: Non-contact processing reduces tool wear lowering maintenance costs.

- **Environmental Protection**: Compared with traditional methods, laser cutting produces less waste and pollution.

### 7. **Typical Applications**

**Fuselage Components**: Used to manufacture fuselage skin, frames, etc.

- **Engine Parts**: Processes high-temperature parts such as blades and combustion chambers- **Interior Parts**: Cuts interior parts such as seats and instrument panels.

### 8. **Future Trends**

- **Intelligence**: Combined with and the Internet of Things, to achieve intelligent production.

- **High-power Lasers**: Improve cutting speed and thickness capability.

- **New Processes**: Such as ultra laser cutting, further improving precision and quality.

### Summary

Laser cutting has become an indispensable processing method in aerospace manufacturing due to its high precision, high, and adaptability to multiple materials. In the future, with the advancement of technology, its application will be more extensive

激光切割在航空制造领域具有重要应用,主要体现在以下几个方面:

### 1. **高精度切割**

- **复杂零件**:激光切割能精确处理钛合金、铝合金等航空材料,满足复杂几何形状的要求。

- **微孔加工**:适用于发动机叶片等部件的微孔加工,精度可达微米级。

### 2. **高效生产**

- **快速切割**:激光切割速度快,尤其适合大批量生产,提升效率。

- **自动化集成**:可与自动化系统结合,实现连续作业,减少人工干预。

### 3. **材料适应性**

- **多种材料**:适用于钛合金、铝合金、复合材料等多种航空材料。

- **难加工材料**:对高强度、高硬度材料的切割效果显著。

### 4. **热影响区小**

- **减少变形**:激光切割热影响区小,减少热变形,保持材料性能。

- **高质量切面**:切面光滑,减少后续加工需求。

### 5. **轻量化设计**

- **减重**:通过精确切割,帮助实现航空器的轻量化设计,提升燃油效率。

- **优化结构**:支持复杂结构设计,提升整体性能。

### 6. **环保与成本**

- **无刀具磨损**:非接触式加工,减少刀具损耗,降低维护成本。

- **环保**:相比传统方法,激光切割产生的废料和污染较少。

### 7. **典型应用**

- **机身部件**:用于制造机身壁板、框架等。

- **发动机零件**:加工叶片、燃烧室等高温部件。

- **内饰件**:切割座椅、仪表盘等内饰部件。

### 8. **未来趋势**

- **智能化**:结合AI和物联网,实现智能化生产。

- **高功率激光器**:提升切割速度和厚度能力。

- **新工艺**:如超快激光切割,进一步提高精度和质量。

### 总结

激光切割在航空制造中因其高精度、高效率和多材料适应性,成为不可或缺的加工手段,未来随着技术进步,其应用将更加广泛。

Application of laser cutting i

Application of laser cutting i

Application of laser cutting i

Application of laser cutting i

Laser cutting is widely used i

Laser cutting is widely used i

The advantage of laser tube cu

The advantage of laser tube cu