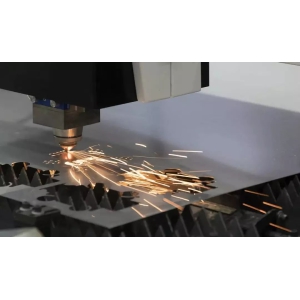

Application of laser cutting in shipbuilding

The application of laser cutting in the shipbuilding industry is mainly reflected in the following aspects:

![]()

### 1 **High-precision cutting**

- **Complex parts**:Laser cutting can precisely process complex shapes and fine details, meeting the demand for high-precision parts inbuilding.

- **Error control**:High cutting accuracy and small error improve the quality of assembly.

### 2. **Efficient production**

- ** cutting**:Laser cutting is fast, significantly shortening the production cycle.

- **Automation integration**:It can be combined with automated equipment to achieve continuous and production.

### 3. **Material adaptability**

- **Various materials**:Suitable for stainless steel, aluminum alloy, titanium alloy and other commonly materials in shipbuilding.

- **Different thicknesses**:Can handle materials of different thicknesses, with strong adaptability.

### 4. **Reduce effects**

- **Low thermal deformation**:Laser cutting has a small heat-affected zone, reducing material deformation and improving cutting quality.

- **Fine cutting**Suitable for materials sensitive to heat.

### 5. **Reduce costs**

- **Reduce scrap**:High-precision cutting reduces material waste.

-Less secondary processing**:The cut edges are smooth, reducing the need for secondary processing and lowering costs.

### 6. **Environmental advantages**

- ** pollution**:Compared with traditional cutting, laser cutting produces less pollution.

- **Energy saving**:Low energy consumption, in line with environmental requirements.

## 7. **Application examples**

- **Ship structure**:Used to cut ship steel plates, ribs and other structural parts.

- **Pipeline system**:Used cut complex pipes and joints.

- **Interior decoration**:Used to cut interior decoration panels and furniture.

### 8. **Technical challenges**

- ** cost**:High initial investment.

- **Maintenance requirements**:Requires professional maintenance and operators.

### Summary

Laser cutting, with its high precision, efficiency, and strong material adaptability, has significantly improved the quality and efficiency of production in the shipbuilding industry. With the advancement of technology, the application prospects will even broader in the future.

激光切割在船舶制造领域的应用主要体现在以下几个方面:

### 1. **高精度切割**

- **复杂零件**:激光切割能够精确处理复杂形状和精细细节,满足船舶制造中对高精度零件的需求。

- **误差控制**:切割精度高,误差小,提升了装配质量。

### 2. **高效生产**

- **快速切割**:激光切割速度快,显著缩短了生产周期。

- **自动化集成**:可与自动化设备结合,实现连续高效生产。

### 3. **材料适应性**

- **多种材料**:适用于不锈钢、铝合金、钛合金等多种船舶制造常用材料。

- **不同厚度**:能处理不同厚度的材料,适应性强。

### 4. **减少热影响**

- **热变形小**:激光切割的热影响区小,减少了材料变形,提升了切割质量。

- **精细切割**:适用于对热敏感的材料。

### 5. **降低成本**

- **减少废料**:高精度切割减少了材料浪费。

- **后续加工少**:切割边缘光滑,减少了二次加工需求,降低了成本。

### 6. **环保优势**

- **低污染**:相比传统切割,激光切割产生的污染较少。

- **节能**:能耗较低,符合环保要求。

### 7. **应用实例**

- **船体结构**:用于切割船体钢板、肋骨等结构件。

- **管道系统**:用于切割复杂管道和接头。

- **内部装饰**:用于切割内部装饰板和家具。

### 8. **技术挑战**

- **设备成本**:初期投资较高。

- **维护要求**:需要专业维护和操作人员。

### 总结

激光切割在船舶制造中凭借其高精度、高效率、材料适应性强等优势,显著提升了生产质量和效率,未来随着技术进步,应用前景将更加广阔。

Application of laser cutting i

Application of laser cutting i

Application of laser cutting i

Application of laser cutting i

Laser cutting is widely used i

Laser cutting is widely used i

The advantage of laser tube cu

The advantage of laser tube cu